|

Vertical Cooling Water Pump

Vertical Cooling Water Pump Specification

- Discharge Pressure

- Up to 16 bar

- Control System

- Optional automatic control panel

- Noise Level

- 80 dB

- Inlet/Outlet

- DN 50 - DN 250 mm

- Mounting Type

- Base Mounted

- Head Size

- 5 - 150 m

- Flow Rate

- 10 - 1800 m/h

- Features

- Corrosion Resistant, Durable, High Efficiency

- Caliber

- Customizable

- Frequency

- 50 Hz / 60 Hz

- Theory

- Centrifugal Pump

- Max Suction

- 7 m

- Voltage

- 380V / 415V (Standard)

- Speed

- 1450 - 2900 RPM

- Working Temperature

- Up to 80C

- Usage

- Industrial

- Material

- Stainless Steel

- Structure

- Vertical Multistage

- Power

- Electric

- Standard

- ISO 5199 / DIN 24255

- Product Type

- Vertical Cooling Water Pump

- Fuel Type

- N/A (Electric Powered)

- Color

- Blue

- Pressure

- Up to 16 bar

- Application

- Cooling Water Circulation, HVAC, Industrial Process

- Suction Type

- Vertical Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-priming (optional)

- Pump Type

- Vertical Cooling Water Pump

- Capacity

- Up to 1800 m/h

- Installation

- Vertical

- Protection Grade

- IP55 or higher

- Bearing Brand

- SKF/NSK (optional)

- Cooling Method

- Water Cooled

- Impeller Type

- Closed/Enclosed Impeller

- Insulation Class

- F/B

- Ambient Temperature

- -10°C to 50°C

Vertical Cooling Water Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 00 Unit Per Week

- Delivery Time

- 00 Week

- Packaging Details

- Through Truck

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO

About Vertical Cooling Water Pump

Capacity 4000 to 100000 GPH, water or Oil lubricated, with combination drive also.

Submersible Pump Technical Details :

|

Pipe Size |

100 to 350 mm dia |

|

Cap. |

300 LPM to 3000 LPM |

|

Head |

10 to 350 mts |

|

Motor Rating |

5 to 250 HP |

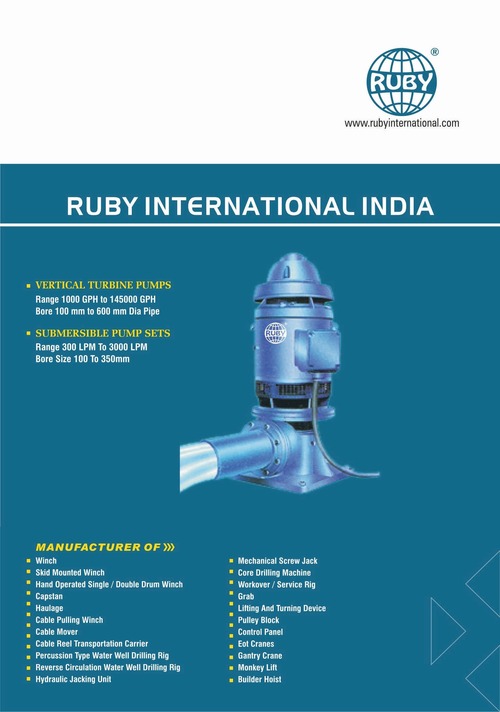

Vertical Turbine Pump :

- Range 1000GPH to 145000 GPH

- Bore 100MM to 600MM Dia Pipe

Submersible Pump Sets :

- Range 300 LPM to 3000 LPM

- Bore Size 100 to 350 MM

Advanced Cooling Capabilities

The vertical cooling water pump utilizes closed/enclosed impellers for efficient movement of liquids, aided by a unique water-cooled system. This feature ensures optimal performance in high-temperature environments, making it ideal for cooling water circulation in HVAC, industrial, and process applications.

Durability and Performance

Constructed from high-grade stainless steel, the pump boasts excellent corrosion resistance and conforms to ISO and DIN standards. It employs SKF/NSK bearings for reliable operation and features mechanical seals for leak prevention, ensuring long-lasting performance even under challenging industrial conditions.

Flexible Installation and Operation

Designed for base-mounted, vertical installation, the pump offers customizable inlet and outlet sizes (DN 50 - DN 250 mm) and can operate within ambient temperatures from -10C to 50C. Optional self-priming and control panel features enhance usability, while electric operation at 380V/415V accommodates diverse power supplies.

FAQs of Vertical Cooling Water Pump:

Q: How does the water-cooled mechanism improve pump efficiency in industrial conditions?

A: The water-cooled system efficiently dissipates heat generated during operation, enabling the vertical cooling water pump to maintain stable performance in high-temperature industrial environments. This prolongs the lifespan of the pump and ensures consistent cooling for process applications.Q: What types of industrial applications is this pump suitable for?

A: The pump is optimized for cooling water circulation in HVAC systems, industrial process cooling, and other applications requiring reliable transfer of liquids. Its corrosion-resistant structure and wide operating range make it suitable for diverse usage in manufacturing, chemical processing, and power plants.Q: When should you consider selecting the optional self-priming feature?

A: The self-priming feature is recommended when applications require the pump to automatically evacuate air from the suction line, such as installations where direct liquid priming is challenging or when frequent start-stop cycles occur. This simplifies maintenance and ensures prompt startup.Q: Where is the optimal installation location for this vertical cooling water pump?

A: For maximum effectiveness, install the pump in a well-ventilated industrial setting, ensuring it rests on a stable base. Vertical mounting is ideal for minimizing floor space usage and for applications requiring vertical suction. Ensure easy access for routine maintenance.Q: What is the process for controlling the pumps operation automatically?

A: You can equip the pump with an optional automatic control panel, allowing for remote monitoring and managing of operational parameters. This system provides safeguards for overload, dry-run protection, and helps regulate flow rate, pressure, and running hours effectively.Q: How does the stainless steel construction benefit long-term usage?

A: The use of stainless steel material significantly enhances the pumps resistance to corrosion and chemical damage, making it durable for extended use in aggressive industrial environments. This reduces maintenance frequency and raises the overall reliability of the system.Q: What are the benefits of using SKF/NSK bearings in the pumps design?

A: SKF/NSK bearings are globally recognized for their robust performance and precision. Their inclusion minimizes friction, reduces noise, and extends the operational life of the pump, contributing to lower maintenance and higher efficiency in demanding industrial applications.

Price 55000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 00 Unit Per Week

- Delivery Time

- 00 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

RUBY INTERNATIONAL INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |